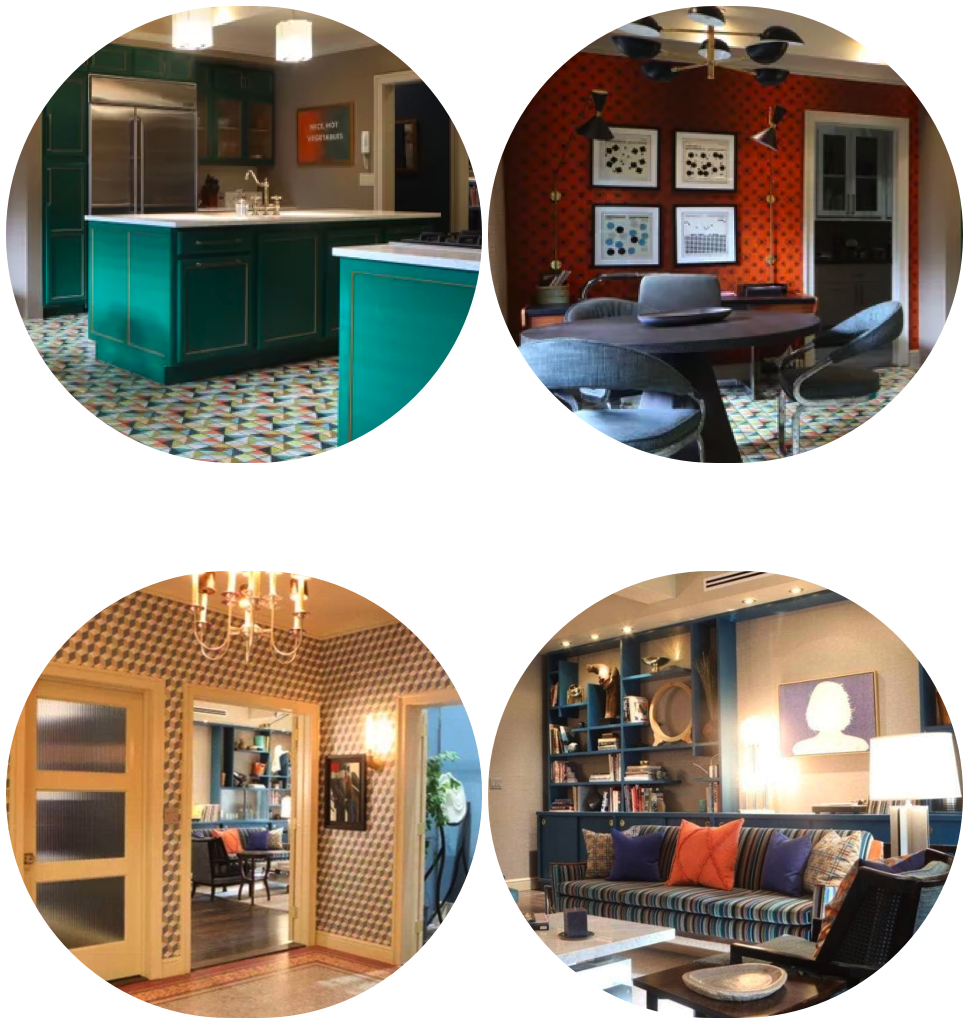

If you have found yourself drawn to any of the apartments in "Only Murders in the Building", it probably says something about your personality. Check out what the design styles of Charles-Haden Savage, Oliver Putnam, or Mabel Mora says about you!

“Your item is backordered.” What does that mean anyway?

Nothing can bring a design project to a screeching halt like a backorder on products. Whether it’s tile, fabric, or furniture, these delays often snowball out to weeks past the completion date. Everyone gets frustrated. The client is aggravated because they’re excited to finish the room and get back to normal life, and the designer is anxious because the client is unhappy.

When you hear the words, “Your item is backordered,” there are several reasons why this can happen. Here are three of the most common reasons:

1) The manufacturer did not anticipate the demand and did not produce enough up front.

This likely the main reason for most backorders that you will encounter. Maybe the item was featured by a major magazine or was part of Oprah’s Favorite Things and the rush for that item was unusually high. Regardless, the projections were short and the manufacturer is scrambling to meet the demand. There’s a logical time-delay for production and therein lies the backorder. Add in shipping delays (see #3) and this could reach out weeks or even months.

2) The manufacturer pre-sold an item that wasn’t quite ready for prime time.

This is the most frustrating on the part of the designer. I have personally experienced this with a designer-exclusive fabric. The memo sample was absolutely perfect and it was used as a central part of a room. What I didn’t know is that they were unable to consistently produce the fabric to match the samples they distributed. When manufacturers are creating new products, sometimes they’ll use trade shows, markets, etc. to gauge interest and generate pre-orders before they decide if they’ll mass produce the item. If they are not able to recreate the sample on a mass scale to meet the demand, backorders are issued until the problems are resolved. In the fabric example, we encountered no less than 4 backorders spanning 6 months. Enough was enough and the relationship between my client and I were strained because of this. (Side note: An alternative was chosen, it looked fantastic, and the client was happy in the end.) These situations, in my opinion, could be minimized with more disclosure from the vendors, but as a precaution, I now check availability on all items before ordering.

3) A product is held up in shipping.

Especially true for international products, such as tile from Italy or textiles from Belgium, there is absolutely nothing you can do but wait. Everyone, including the manufacturer is helpless when it comes to customs delays at U.S. ports. Inside the US, sometimes several manufacturers (especially furniture companies) will combine shipments with independent cross-country freight haulers to minimize shipping costs. Then, you’ll be put in part of a large stop schedule that could take several weeks as the truck makes it’s maze across the country making deliveries. The only option here is to pay to ship the product on your own which is usually extremely expensive.

In the end, it’s a waiting game. And then, the question arises “Is this product worth it?” “Is there a suitable substitute that is available now?” Consult your designer and see what her opinion is and all involved will need to show to some patience. There are almost always options, but sometimes that particular product is just what a room needs. But it’s imperative that you communicate, communicate, communicate with each other as to not get angry and damage the client/designer relationship.